Welcome to SHIELD Holdings GmbH - your specialist for tunnelling machines! With us, you can rent high-quality construction machinery that is specially tailored to the requirements of tunnel construction. With our wide range of products, we offer you a variety of solutions to successfully implement your construction projects.

XCMG's powerful fleet of machines is in action on construction sites.

Tunnel construction places enormous demands on people and machinery. Our customers in this industry face enormous challenges every day, from hard rock layers to precise underground work. We provide specialised construction machinery to meet these unique requirements. At the heart of our range are powerful civil engineering machines that can reliably construct diaphragm walls and foundations, even at great depths – the basic prerequisite for any successful tunnel construction project. Our fleet of excavators covers all size classes, including heavy tracked vehicles for large-scale excavation work, manoeuvrable wheeled excavators, and compact machines for the narrowest tunnel sections. All machines can be equipped with hydraulic hammers for the hardest rock formations if required. Our range of loaders includes large wheel loaders for moving rock blocks weighing several tonnes, universal backhoe loaders that can switch flexibly between loading and digging tasks, and compact mini loaders that can work with precision in confined areas. Our lifting technology includes mobile cranes with various load capacities for heavy tunnel construction elements, all-terrain cranes for rough terrain, and telescopic loaders with a long reach for inaccessible areas. Our tunnel construction customers particularly appreciate the robust design of all our machines. They can operate reliably in three shifts and are optimised for the challenges of underground construction. Our maintenance team minimises downtime because, in tunnel construction, every hour counts. Planning a tunnel construction project? We can provide the ideal combination of machines for your project.

Difficulties in assembling tunnelling machines underground

Assembling large tunnelling machines is a demanding task that poses special challenges underground. Why is this? Limited space Limited space is one of the main challenges. Tunnelling sites often have limited space for the installation of large machines. Thorough planning and coordination is required to ensure that all components can be installed efficiently and safely. Lighting and visibility Safety aspects Workplace safety is paramount. In a tunnel with limited space and potential risks, it is imperative that strict safety guidelines are followed. This includes personal protective equipment, training and constant vigilance. Conclusion Installing tunnelling equipment underground requires experience, precision and extensive planning. By addressing these challenges, projects can be carried out safely and efficiently, resulting in successful tunnelling projects.

Logistical challenge: transporting a tunnel boring machine

Logistical challenge: transporting a tunnel boring machine Transporting heavy construction machinery, especially tunnel boring machines (TBMs), is an impressive logistical feat. Using the example of a transport from Germany to Turkmenistan, we show what needs to be considered. Key data of the transport: - Duration: approx. 4 weeks - Vehicles required: approx. 32 trucks - Heaviest single part 68 tonnes The transport will take place in several stages 1. dismantling: The TBM will be dismantled into transportable parts. 2. loading: Special lorries are loaded for safe transport. 3. route: The route crosses several countries and requires careful planning. 4. customs clearance: Special permits are required at border crossings. Once at the destination, assembly begins. According to chief engineer Evgeni Kamnev, this takes about a month. The tunnel boring machine is reassembled piece by piece and made ready for use. This complex process underlines the importance of professional logistics when transporting heavy machinery. It is the only way to ensure that highly specialised equipment can be used worldwide and that major projects can be carried out efficiently.

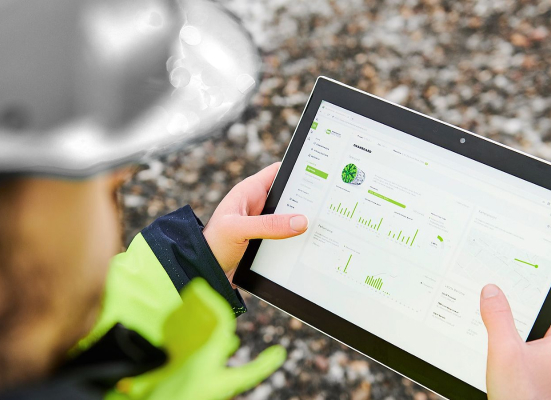

Segment production systems delivered to Ashgabat

On 20 May 2024, we delivered the first segment production systems to Ashgabat as part of our partner's project "Lowering the groundwater level and constructing underground drainage tunnels for the disposal of sewage and rainwater in the city of Ashgabat". Segment production systems in operation Tunnelling projects place special demands on tunnel construction due to varying diameters, soil conditions and routes. Perfectly formed segments, delivered on time, must last up to 100 years in the tunnel. Turnkey solutions are required. Precision is the key to segment production. The design of the segments takes into account important parameters such as route, statics and tunnel cover. The segments are designed so that the geometry of the rings and segments, as well as the seal, are optimally matched. This results in segments that are easy to handle, stable and watertight.

REEF BORING MACHINE

The Herrenknecht Reef Boring Machine (RBM) safely and efficiently creates horizontal and ascending boreholes with inclinations of up to 40°. In stable rock with up to 300 megapascals and with excavation diameters of up to 1.5 meters, the RBM achieves borehole lengths of up to 40 meters.

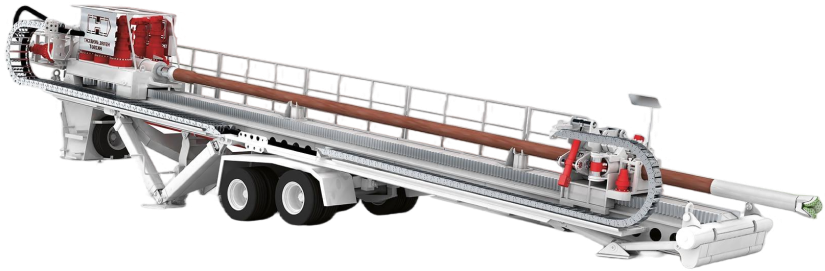

HORIZONTAL DIRECTIONAL DRILLING (HDD)

With horizontal directional drilling rigs from Herrenknecht, pipelines can be installed under rivers and infrastructures quickly, economically and with minimal impact on the environment. Examples of pipeline applications include the transport of oil, gas or wastewater as well as district heating, high-voltage power lines, cable bundles for telecommunications and much more. HDD Rigs are versatile and are mainly used in stable loose soils and consolidated rock.

BOXHOLE BACKREAMING MACHINE (BBR)

The Herrenknecht Boxhole Backreaming Machine (BBR) bores and reams ore passes and ventilation shafts with diameters of up to 3.5 meters. Based on the proven BBM technology, the BBR is characterized by high efficiency and high safety standards. Upon request, Herrenknecht will supply the BBR with a project-specific lowering unit. With this, lining of the shaft can already be done parallel to the reaming operation, saving time and increasing safety.

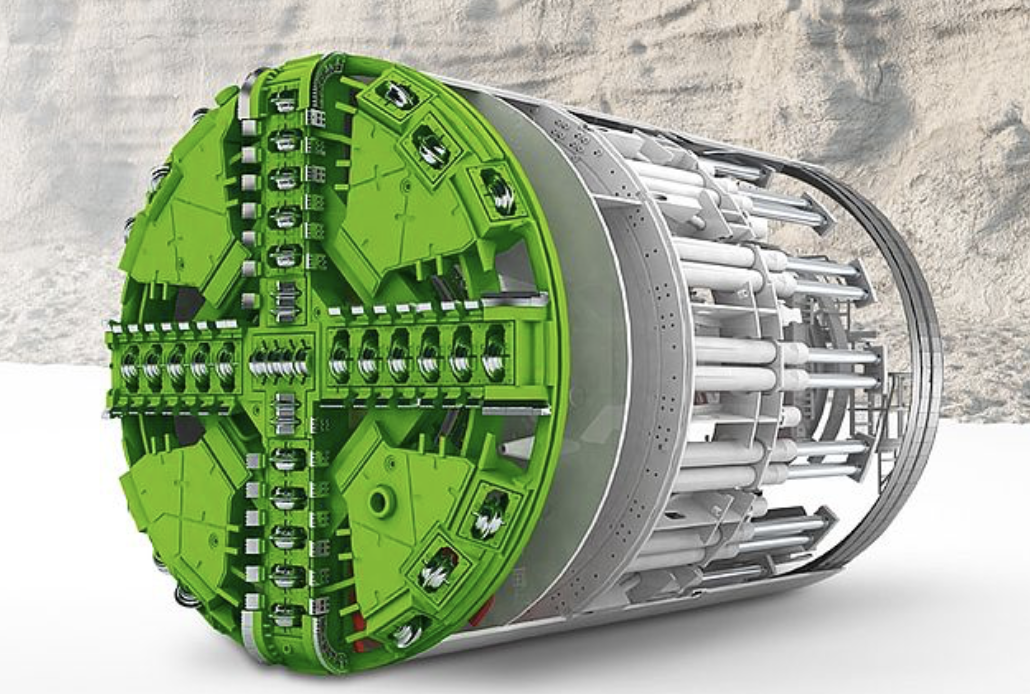

Tunnel Boring Machine Herrenknecht / EPB SHIELD

Revolutionising Underground Construction: EPB Shield Tunnel Boring Machines In the world of tunnelling, Earth Pressure Balance (EPB) Shield machines are changing the game. These innovative tunnel boring machines (TBMs) excel in soft ground conditions, providing a fast and efficient solution for underground construction. Key features: - Ideal for soft ground with low water permeability (clay, silt, loam) - Diameter range: 1.7-16m - Uses excavated material as support How it works: 1. A cutting wheel excavates the soil 2. Excavated material is mixed into a malleable paste 3. The pressure of the paste is balanced by the pressure of the surrounding soil 4. Excavated material is removed by screw conveyor Advantages: - High feed rates in cohesive soils - Versatile use due to soil conditioning - No additional support required - Minimal surface disturbance EPB Shields can be conditioned to suit different soil conditions, extending their usefulness. This makes them ideal for urban tunnelling projects where minimising surface disturbance is critical. As cities grow and infrastructure needs increase, EPB Shield TBMs will play a key role in shaping our underground future. Their combination of speed, efficiency and adaptability makes them the first choice for modern tunnelling projects.

Our reliable and friendly service sets us apart. Customer satisfaction is our top priority and we do everything we can to provide you with a smooth and efficient rental process. From booking to delivery and return of the machines, we ensure that you can concentrate fully on your construction project without having to worry about logistics.